Sistemi per il trasporto su scale, sollevamento e movimentazione di carichi pesanti!

Carrelli Saliscale Elettrici a Batteria

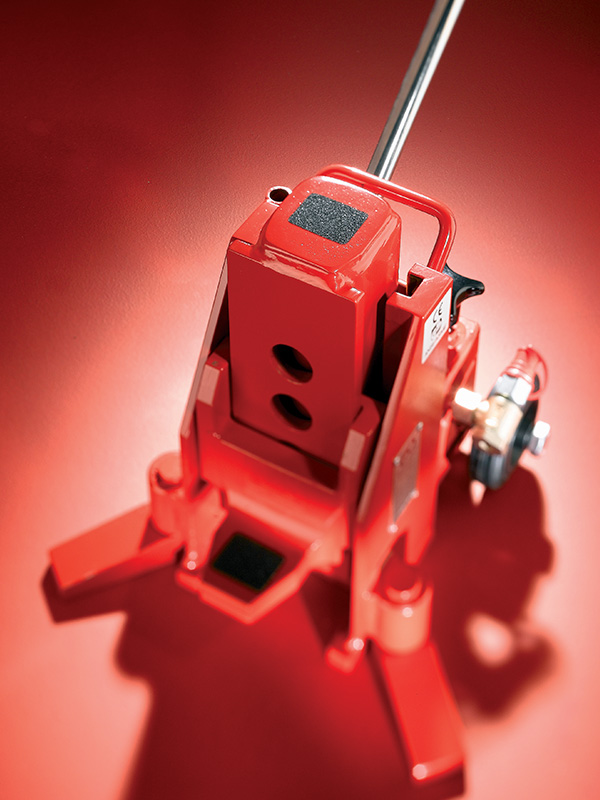

Sollevatori e Martinetti Idraulici

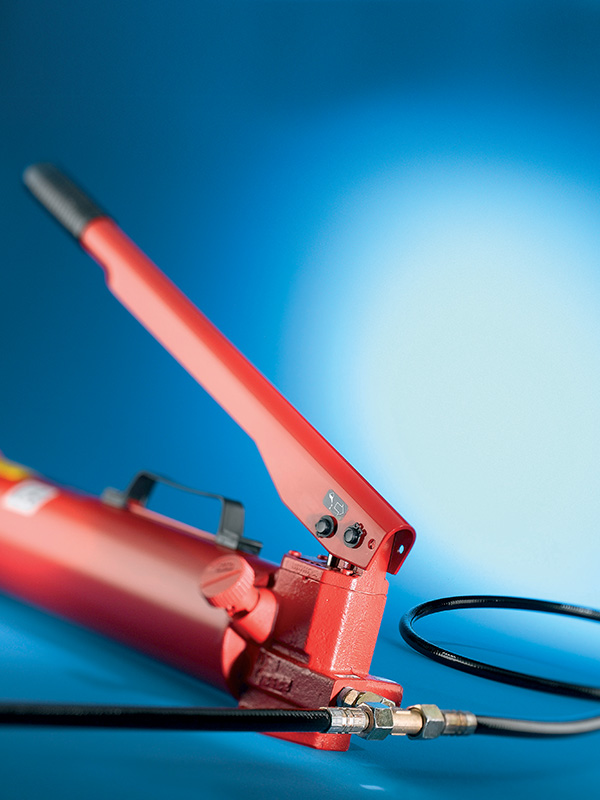

Pompe Idrauliche Elettriche e Manuali

Cuscini di Sollevamento

Carrelli da Trasporto 90°

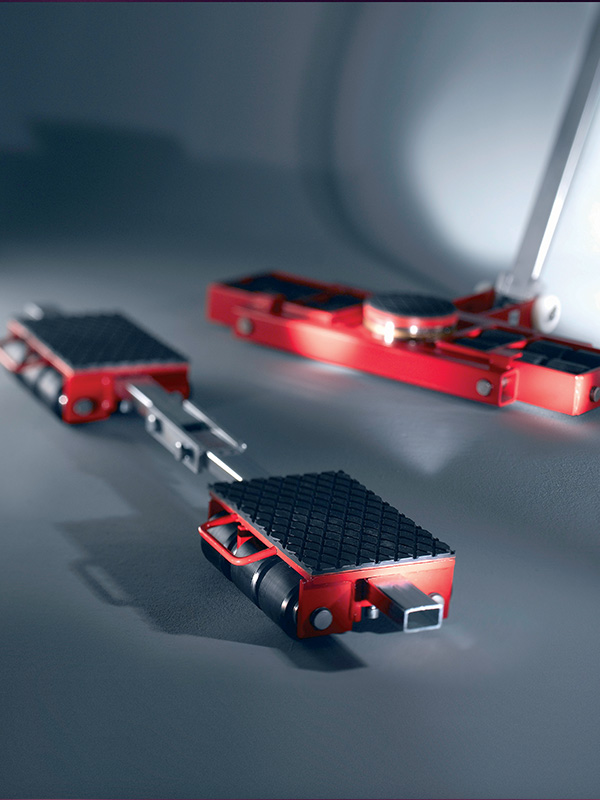

Le rulliere da trasporto GKS-Perfekt di Nuova Tecnica sono l'ideale per il trasporto di carichi pesanti senza alcuno sforzo e in totale sicurezza per l'operatore. Modelli disponibili nichelati per l'impiego in camere bianche.

360°">

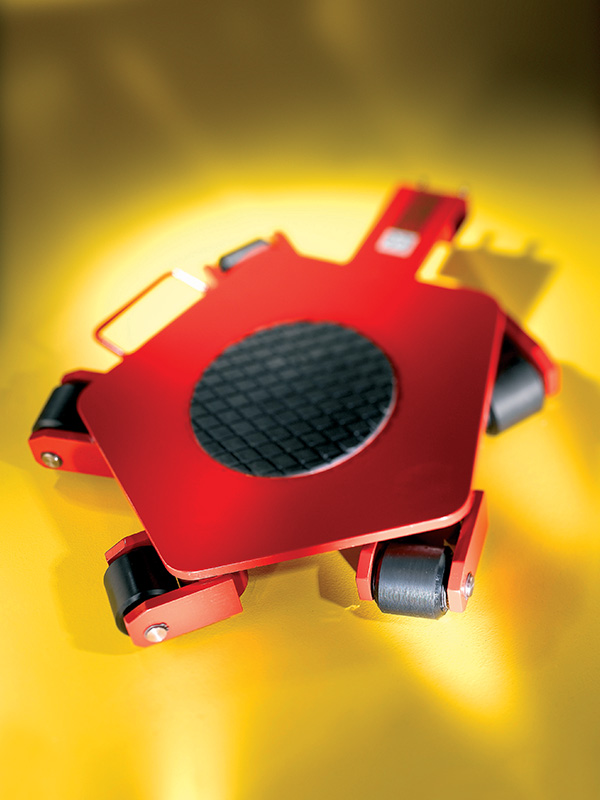

360°">Carrelli Girevoli

360°

Spostano in ogni direzione con movimenti precisi qualsiasi carico ingombrante di peso compreso tra 1 e 12 tonnellate. Si possono utilizzare 3 o 4 carrelli girevoli contemporaneamente tramite apposite barre di guida.

Ruote Industriali

Trasporto Motorizzato

Studiati appositamente per trasportare pesi fino a 40 tonnellate e vengono impiegati specialmente per linee di assemblaggio, logistica interna e operazioni di movimentazione o di installazione macchinari.

Spingitore Elettrico

Riduce lo sforzo manuale e accelera le operazioni aziendali, movimenta merci in ogni direzione fino a 30 tonnellate. Manovrabili da una sola persona senza sforzi e in sicurezza: operazioni più veloci, aumento della produttività.

Salite in una nuova dimensione del servizio

I nostri servizi

Progettazione e produzione

Consulenza Tecnica

Assistenza tecnica

Quello che distingue i nostri prodotti e

servizi per la movimentazione

Certificazione ISO 9001

Assistenza clienti

Trasporto rapido, sicuro ed efficiente

Articoli Blog

Guida alla sicurezza sul lavoro nella movimentazione di carichi pesanti

Guida alla sicurezza sul lavoro nella movimentazione di carichi pesanti

La movimentazione di macchinari pesanti è una delle attività più comuni nei contesti industriali, logistici e produttivi. Coinvolge operazioni come il sollevamento, il trasporto e il traino di materiali o macchinari, che avvengono

...Innovazione e Affidabilità in Movimento: la nostra partecipazione alla Fiera A&T Nordest di Vicenza 2025

Innovazione e Affidabilità in Movimento: la nostra partecipazione alla Fiera A&T Nordest di Vicenza 2025

La nostra azienda ha partecipato alla Fiera A&T Nordest di Vicenza 2025, presentando i sistemi di trasporto GKS-Perfekt, gli spingitori SP fino a 30 tonnellate, i cuscini di sollevamento e le ruote industriali ad alta portata, di livellamento e ammortizzate.

Trasloco industriale: smontaggio, trasporto e montaggio di macchinari industriali

Trasloco industriale: smontaggio, trasporto e montaggio di macchinari industriali

Un trasloco industriale non riguarda solamente lo spostamento di attrezzature, ma implica la pianificazione tecnica, la movimentazione sicura e la ricollocazione di impianti industriali completi, spesso all’interno di capannoni operativi o in spazi con accesso limitato.